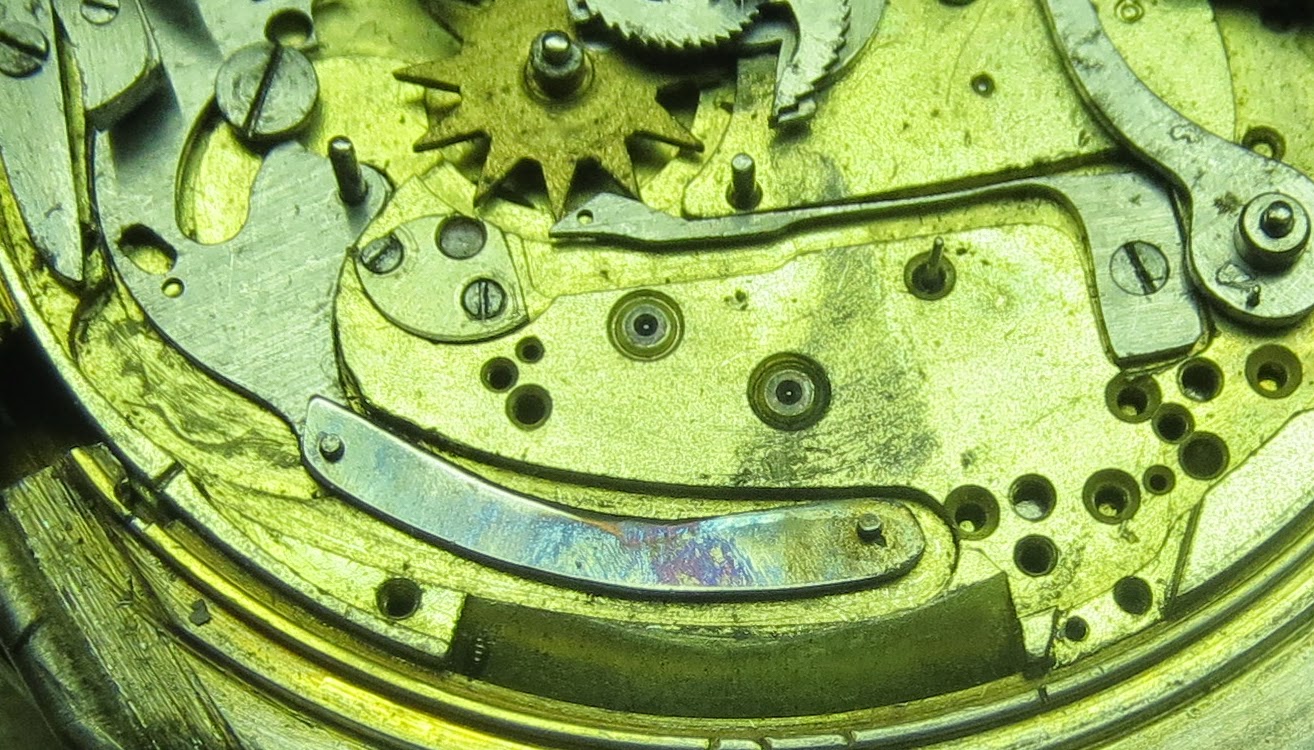

This minute repeater was non-running, would not wind or set and the repeater was not working as received. Initial investigation showed the following:

A: Repeater operating lever has non-original operating slide that is too short and too rough to operate the repeater.

B: Clutch wheel operating lever out of wheel slot.

C: Non-original trip dog keeper.

D: Slide sticky and stiff.

E: Major problem is the minute wheel is missing 6 teeth, has one poorly replaced tooth and one tooth damaged by filing. Plus, the center pinion is missing one leaf (tooth).

Repairing the repeater (A:)

The repeater operating slide required making a new slide because the current slide was too short to achieve striking beyond 7 hours and too rough to run smoothly. A suitable piece to high quality steel of the correct gauge was found to be a piece of a large case knife snap off blade.

The blade piece was heated to red and allowed to cool slowly to remove the temper and a 0.5 mm hole was drilled for the screw-in post.

The hole was tapped for a screw.

A screw had to be made from scratch for the right size and shape new post for the slide, first turning steel stock on the lathe.

and then making the threads with a screw die.

The finished screw will have the head filed off after it is in place and spot welded from the bottom, leaving a strong steel post in the slide plate.This 0.5 mm screw will have to take all the pressure of a person's thumb or finger operating the repeater slide of the watch.

The slide was shaped and the post installed and then the slide and post were both hardened and tempered for strength.

On reassembly, the repeater worked.

Fixing the clutch wheel lever (B:) was simple to do by loosening the hold-down screw and moving the clutch lever into the clutch wheel slot. This let the winding and setting system work.

Checking the operating of the hammer trip dogs showed that the non-original keeper (C:) worked fine as it was.

The sticky repeater slide (D:) was fixed by cleaning rust off of the internal slide and shaving it down slightly to allow it to clear the case braces in the slide channel.

Fixing the minute wheel and center staff pinion (E:) was a major undertaking. First, with the set lever working, I checked to see if the minute wheel would still set the time by spanning two leafs on the pinion as it went past the missing leaf, but it would not. The specifications for both wheels were so tight and unusual that no suitable replacements could be found. This meant that teeth would have to be repaired on both the minute wheel and center pinion. On a minute repeater, this part is not a true canon pinion and it is an integral part of the repeater minute snail and surprise piece assembly.

A suitable larger brass wheel of the right gauge was selected for the damaged wheel.

The donor wheel was cut down on the lathe to the right diameter.

Then the wheel cutting and indexing attachments were set up on the lathe to cut new teeth on the wheel blank. This was a 36 tooth minute wheel.

New teeth were cut.

Next, a rounding up machine was set up and aligned to shape the tooth profile of the new teeth correctly and the wheel was machined until the tooth profile and wheel diameter was as required.

The new wheel matches the damaged wheel. Only the teeth will be used as the center pinion does not match the old wheel.

Good teeth are cut from the new wheel to replace bad teeth on the original wheel.

Bad teeth are cut away from the original wheel and the new teeth carefully matched in place.

The new teeth are soldered in place with heat from below so solder is wicked into the entire joint.

Solder is filed flat and the wheel tested for strength and true.

Repairing the center pinion:

The pinion staff and shoulders for the repeater snails are cut from a single piece of steel so the pinion can not be replaced.

First, the surprise piece with quarter snail is removed and then the minute star snail is removed from the arbor by breaking the staking rivet.

New metal is microscopically welded onto the broken pinion. 18K solid gold is used because it flows and welds to the steel strongly and it is hardened by the welding process. Gold welded onto steel is surprisingly strong.

A new tooth profile is filed from the gold.

The minute star snail is riveted (staked) back on to the arbor against the center pinion and tested for strength. Then the surprise piece with quarter snail are re-assembled and tested.

The repaired minute wheel and center staff pinion are re-installed and tested. Now the motion works runs correctly, the time can be set and the minute repeater works correctly.

Total time spent was 11 hours, 15 minutes (not counting any time to take pictures and type the blog).